Bi-Monthly Informational Guide

MBC, Inc. Quality Tips

Process Failure Mode Effects Analysis (PFMEA)

A Customer Complaint Reduction Tool

Continuous improvements, customer satisfaction, process efficiency, and profitability, are these things in conflict with each other? What are the common characteristics of these four buzz words of today’s business? Which is more important; profitability or customer satisfaction?

Business cannot achieve customer satisfaction in the long term if the business is not profitable. Likewise a business cannot be profitable in the long term if they don’t have satisfied customers.

On the surface Process Efficiency and continuous improvement seem to be related characteristics.

How is Process FMEA related to these

four fundamental and important issues?

Many businesses in today’s economy look at some of the quality tools, such as the process FMEA, as burden or overhead. If this tool is only used to obtain a “check-mark” for a task completed as a customer requirement. Then yes process FMEA is reduced to overhead.

It is the responsibility of the organization’s resources and leadership team to make the process FMEA a valuable tool. Over the course of the last two “Quality Tips” I have presented the process FMEA as a valuable tool and as a management tool for cost reduction as well as process improvement.

Now, let’s take a look at how this valuable tool becomes a living document that has the ability to greatly improve customer satisfaction, profitability and lead to process improvements.

Process FMEA is simply risk analysis of business or manufacturing process activities. To complete this analysis the three questions of FMEA must be ask and answered honestly.

1. What is the requirement?

Example – Secure the bolt to the proper torque specification.

2. What is the failure mode of the requirement?

Example – Bolt not torque to Specification.

3. What is the effect when the failure mode occurs?

Example – Loose component causes rattling noise when used by the customer.

The effect of the failure mode is defined as the effect on the customer (customer may be internal or external). Therefore the Process FMEA is an attempt to address all actual and potential customer impacts or failure modes. If this were accomplished at 100% accuracy then the customer would never again receive a product that did not provide 100% satisfaction. The reality is the FMEA analysis is completed by people, people are not perfect. This ensures us that some items will be overlook, omitted, or analyzed inaccurately. When this occurs there is a higher likelihood that products that do not bring 100% satisfaction to customers will be produced and shipped.

First let’s examine the impact on external customers!

When customer complaints are received it is generally the result of product or service specifications or functional requirements that are non-conforming. When this occurs the analyst must look at the customer  complaint and determine if this particular “failure-mode” was identified in the Process FMEA. If it is determined that the failure mode was not identified in the Process FMEA, then it is little wonder that this particular non-conformance was delivered to the customer and a complaint was received.

complaint and determine if this particular “failure-mode” was identified in the Process FMEA. If it is determined that the failure mode was not identified in the Process FMEA, then it is little wonder that this particular non-conformance was delivered to the customer and a complaint was received.

It is quite a simple step to add this previously unidentified failure mode to the Process FMEA and complete the analysis, problem solving and put the proper process controls and/or detections in place to ensure the customer does not receive unsatisfactory products or services in the future. This is an example of a Process FMEA oversight.

The second scenario; is the customer complaint failure mode was indeed included in the Process FMEA. When this is the case the analyst must determine several things;

1. If the failure mode was identified was the “Effect of the Failure” properly identified?

2. If the effect of the failure was properly identified was the “severity” ranking properly assessed and ranked?

3. Was the “occurrence” properly assessed and ranked?

4. Was the “detection” properly assessed and ranked?

It is very likely one or more of the above were not addressed or the severity, occurrence, detection (SOD) values were under ranked. If one or more of the SOD’s are under ranked the resulting RPN value or Risk Priority Number would have been incorrectly low. This may have resulted in inadequate or missing process controls and/or detection activities. The result is a condition that would allow non-conforming products or services to be shipped to customers, resulting in the aforementioned customer complaint.

When this condition is found it is the FMEA team’s responsibility to correct the discrepancies, reevaluate the severity, occurrence and detection values and put the proper process controls in place to control the product or service provided to the customer.

Now let’s examine the impact on internal customers!

The internal customer issues are caused by the same two conditions as the external customers.

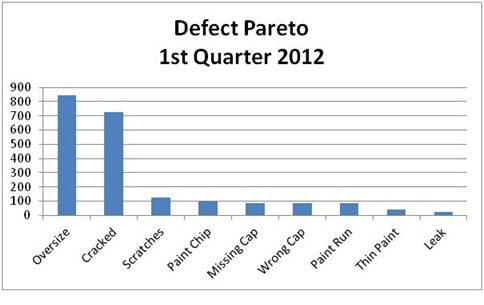

The difference being in how internal customer issues are identified, in most businesses the Process FMEA resource team would not be able to react to every individual scrap or rework condition. Therefore a Pareto of the  defects must be developed and the FMEA team is to address the identified items in rank order. Using the same criteria as above first is the failure mode identified on the FMEA, or if it is identified was it properly analyzed?

defects must be developed and the FMEA team is to address the identified items in rank order. Using the same criteria as above first is the failure mode identified on the FMEA, or if it is identified was it properly analyzed?

As the team attempts to put together a comprehensive FMEA as defined in these three Quality Tip Newsletters, the team must make sure they have received proper training from a competent facilitator. Has the trainer had first hand FMEA experience and actually produced results for the organization? No every consultant or trainer meets this requirement.

_____________________________________________________________________________

For additional information about the FMEA Process translated into a valuable tool for addressing customer complaints both internal and external, you may contact the President of MBC, Inc. at anytime; Phone 931.637.1446, or E-mail – Bmartin@MBCIncorp.com

Thank You

Bill Martin – President

MBC, Inc.

931.637.1446